Achieve Project Success with the Right Methods and Equipment

If you’ve installed landscape lighting, underground sprinkler systems or drain tile running through a lawn, you understand the demanding work caused by a sidewalk or driveway blocking your path. Boring under cement may not be a part of every job you do, but it’s nice to know you have a solution available for this situation.

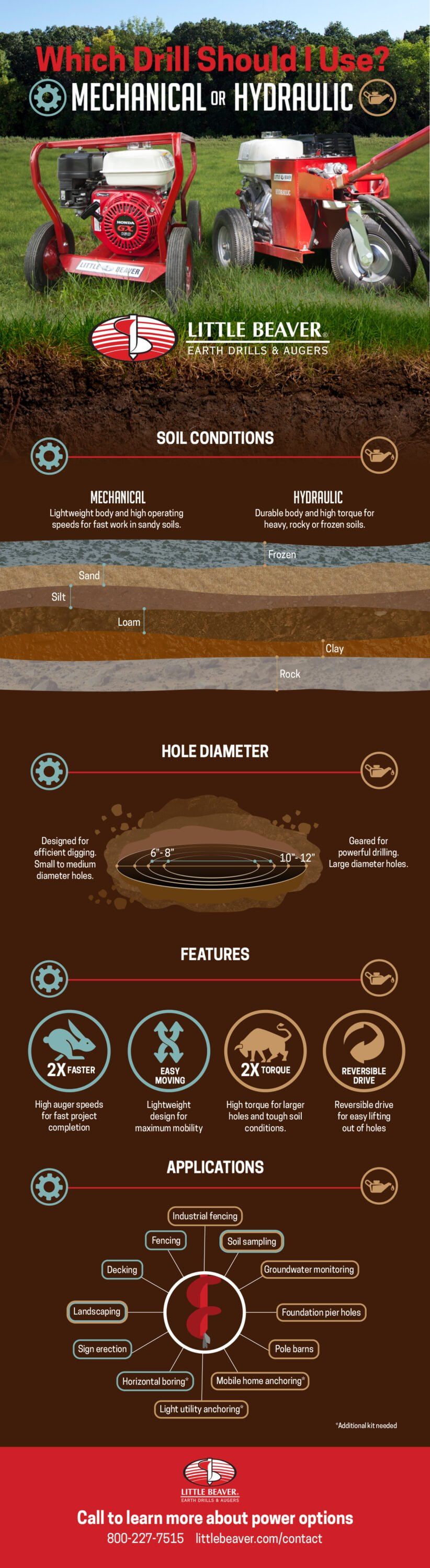

With help from Little Beaver’s horizontal boring attachments, you can get underneath almost any concrete obstacle to install conduit, pipe and irrigation systems. The attachments pair with our Mechanical Earth Drills. Before you start your next project that involves burying lines, consider your horizontal boring options and learn best practices.

Sidewalk or Driveway

The first step is to evaluate the size of the project. This will help you determine the equipment best suited for your needs. Smaller jobs, such as boring under sidewalks to connect a water line or run wires for lighting, are best done with a sidewalk boring kit that easily bores up to 5 feet.

Larger projects — as long as 50 feet — can be tackled with the driveway boring kit. This attachment bores smoothly under a street or driveway, which makes it ideal for installing underground irrigation systems. After choosing the proper attachment, you can get started with your boring project.

Digging In

First, gather your horizontal boring kit, mechanical drill and either a trenching machine or a round point hand shovel and spade. For wet drilling you will also need a garden hose, 3/4-inch Schedule 80 water pipe and 3/4-inch pipe couplings.

Then, dig a small starter trench so that you can reach the correct depth and angle as you start to bore. The dry boring kit requires a 6-foot-long trench 6 inches below the bottom of the concrete slab. When using the wet auger kit, dig a trench 15 feet long. Trench depth is important, as a deeper trench will greatly reduce the risk of cracking concrete while boring. Then move to the opposite side of the pavement and dig a shorter trench to receive the drill as it passes from under the pavement.

Since this is such a low-torque job, the torque tube is not needed. Disable it by attaching the horizontal drill key to the tube connector, which activates the safety interlock. Drill setup varies slightly for each auger kit, so follow the instruction manual for finer details. Before you begin, call 811 to verify there are no existing utilities in the digging area and follow all other safety precautions.

Here to Serve You

Little Beaver Mechanical Earth Drills are designed to make horizontal boring easier so you can take on more boring projects in a shorter period of time. To complete your next horizontal boring job quickly, efficiently and safely, watch our attachments in action. Then contact us to get the horizontal boring attachment that fits your next project. Do not let sidewalks and driveways get in your way.