Small Spaces, Big Insights

Soil sampling in confined spaces is a critical step in construction, urban agriculture and foundation repair projects. However, not every project has the space to accommodate a big soil sampling rig. For projects in confined spaces — such as a basement, backyard or on a sensitive historical site — finding equipment that can dig deep enough while fitting into these tight areas can be a challenge.

A Big Beaver Earth Drill makes soil sampling easier in restricted access locations by offering a compact, maneuverable design that is precise to control and safe to run with only one operator.

Maneuverability in Tight Spaces

The Big Beaver excels at foundation repair, efficiently drilling pier holes up to 16″ in diameter. A simple crank mechanism lets you align the mast in any position up to 15 degrees from vertical.

The right equipment can make or break a soil sampling project with space limitations. Handheld samplers might seem like a good solution for tight spaces, but they don’t always reach deep enough to procure the samples you need. Alternatives, such as automated options, can be costly while truck- or trailer-mounted rigs can’t fit into small work areas.

Another challenge is that these projects often take place in urban developments, near or beside houses and fences. Contractors need portable, gentle equipment that doesn’t damage turf, sod or landscaping with its tires or heavy weight.

The Big Beaver is only 26 inches wide and 80 inches tall, making it compact enough to fit into an elevator and through a doorway or gate and short enough to stand upright under the eaves of a house or other areas with low overhead clearance. The auger tilt angles up to 15 degrees to get as close to a structure as possible. At 675 pounds, the drill is light enough to minimize damage to lawns and landscaping.

Depth Precision

Each soil sampling project requires the soil to be collected at a different depth. Some projects, like soil sampling for a home garden, only require sampling to about 4 inches deep. This can be completed with a simple hand sampler, but many projects require deeper digging. Construction and foundation repair projects can vary between 3 feet deep up to 100 feet deep.

- Utility: 3-10 feet deep

- Foundation Repair: 3-30 feet deep

- Construction: 10-100 feet deep

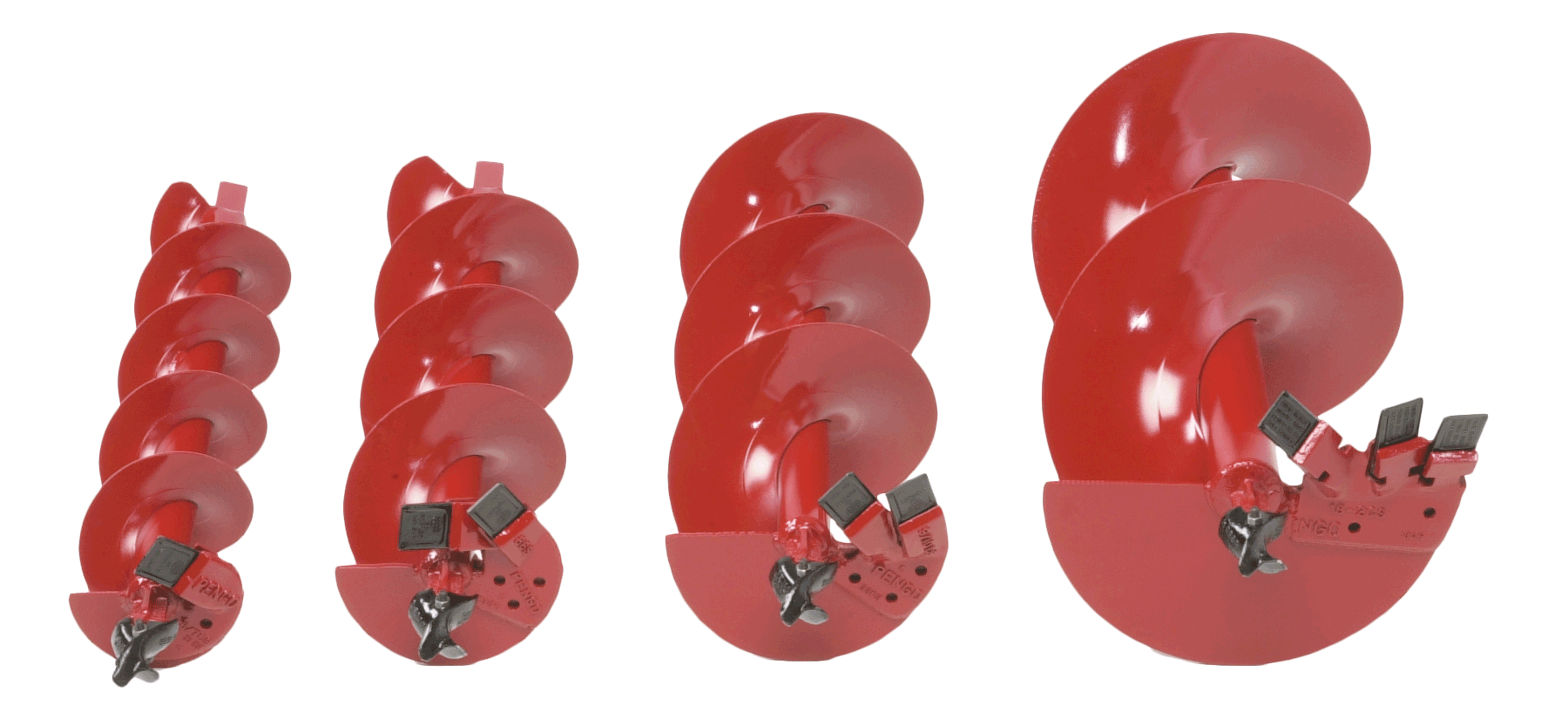

These depths vary based on soil type, what project is being carried out and local regulations. Some local agencies require certain soil sampling depths to be tested before construction takes place. The Big Beaver can dig to 30 feet with a 16-inch auger and up to 100 feet with a 6-inch auger, depending on the soil conditions.

Safe Drilling

The Big Beaver is a standalone auger drill rig that allows for safe one-man operation. It features a torque tube that redirects dangerous kickback away from the operator to the power source. The torque tube connects to the drill at three different points on the frame, which allows for nine different torque tube positions. This lets operators position the drill in the most convenient way possible.

In basements or other enclosed spaces, operators should place the engine carriage outside with an extension hose running to the drill. Removing the engine from the room protects against dangerous fumes while working in close quarters. When doing so, operators should anchor the drill to the floor with screw or concrete anchors. This protects the operator from counterrotation by preventing the drill from jerking or tipping when encountering an underground obstacle.

Soil Sampling with the Big Beaver

Restricted spaces shouldn’t hold up your soil sampling project. When automated, trailer- and truck-mounted options just don’t work, a Big Beaver earth drill makes projects easier, safer and more precise. Check out our Big Beaver Earth Drill and soil sampling options to learn more.