Choosing Equipment to Increase Profits

Improving ROI for Rental Centers

At both the collegiate and professional level, great quarterbacks are few and far between — and for good reason. In addition to the hard work and dedication it takes to reach that level of competition, quarterbacks face a slim margin of error on every down. To complete a single pass, a quarterback must know the roles of defenders and anticipate their actions, account for the speed and timing of the receivers, and, of course, make a precise throw into a small and fleeting window of opportunity.

Running a rental center can feel much the same. Discovering efficient, safe and durable equipment, like Little Beaver Mechanical Earth Drills, is a game-changing play.

The One-Man Approach

Rental centers should think of equipment in terms of usability. A greater emphasis on user-friendly equipment attracts a broader variety of renters. This is true for both crews looking to supplement their fleet with additional equipment options, and for individuals needing a tool for DIY landscaping.

Little Beaver Mechanical Earth Drills provide high auger speeds — up to 360 rpm — for fast hole digging. Many drills require two operators to mitigate the risk of injury from the torque and kickback associated with the drill’s power and speed, but our drills take a different approach. Little Beaver Mechanical Earth Drills feature engines that are mounted on a separate carrier attached to the drill’s handles via a steel torque tube. The drill’s torque and kickback are transferred to the engine carrier, as opposed to the operator, making safe one-person operation possible. This means you can offer unmatched efficiency for contractors, and a one-operator option for homeowners tackling their own projects.

Add Opportunities

Add Opportunities

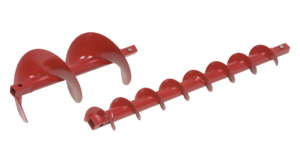

Solutions to expand an earth drill’s capabilities — and, in turn, your rental opportunities — are another option to consider. At Little Beaver, we offer snap-on augers that take seconds to change, allowing for a quick adjustment to match your customer’s drilling requirements. We offer a full range of diameters between 1.5” to 16” in both 36” and 42” lengths, meaning you can provide a versatile line of augers for a variety of rental needs.

Meanwhile, our horizontal boring kits add to our Mechanical Earth Drill’s capabilities. These kits give the earth drill capabilities similar to a horizontal boring machine for drilling underneath sidewalks or driveways, increasing the equipment’s rental applications.

Benefit from Durability

Equipment repairs inevitably take time to complete. Even a basic repair can lead to as much as a full day of lost rental time both from the renter and your rental center. That’s why our Mechanical drills have features such as a heavy-duty transmission and centrifugal clutch to lessen the likelihood of untimely breakdowns. When drilling, it’s common to strike rocks, roots and other buried objects. If the auger hits an object, the centrifugal clutch releases, stopping rotation and preventing damage to both the auger and transmission.

Solutions for Success

While quarterbacking a successful rental business is no easy task, finding solutions that increase the gap between revenue and ruin is a great way to work toward this goal. Simple solutions to versatility and maintenance times are among the easiest ways to manage both margins for error and profit margins. Any equipment that can single-handedly increase a business’s capacity to take on additional renters while reducing the cost of maintenance is worthy of an MVP award.

To learn more about how rental centers can benefit from our earth drill options, contact Little Beaver today.

Eddie Zansler, owner of North Dallas Foundation Repair, has been in the business for more than 25 years. He knows how important it is to have a hardworking crew and perhaps even harder-working machinery on a jobsite. When it comes to installing concrete piers, Zansler swears by the

Eddie Zansler, owner of North Dallas Foundation Repair, has been in the business for more than 25 years. He knows how important it is to have a hardworking crew and perhaps even harder-working machinery on a jobsite. When it comes to installing concrete piers, Zansler swears by the

Maximizing Manpower

Maximizing Manpower The Proof Is in The Profit

The Proof Is in The Profit

Perhaps the most obvious question is why choose hydraulic earth drills in the first place? With a durable body and higher torque than mechanical options, a hydraulic drill can bring more power to a drilling project. Hydraulic earth drills can also drive larger diameter augers with

Perhaps the most obvious question is why choose hydraulic earth drills in the first place? With a durable body and higher torque than mechanical options, a hydraulic drill can bring more power to a drilling project. Hydraulic earth drills can also drive larger diameter augers with  The hydraulic system in

The hydraulic system in

The first step in purchasing an earth drill is

The first step in purchasing an earth drill is  Both the mechanical and hydraulic earth drills feature our innovative torque tube. This tube redirects the torque away from the drill by transferring kickback from the auger to the power source. Most drills without torque protection require two operators. However, because our earth drills come with the torque tube, the standard handle on our drills is the one-man handle.

Both the mechanical and hydraulic earth drills feature our innovative torque tube. This tube redirects the torque away from the drill by transferring kickback from the auger to the power source. Most drills without torque protection require two operators. However, because our earth drills come with the torque tube, the standard handle on our drills is the one-man handle.