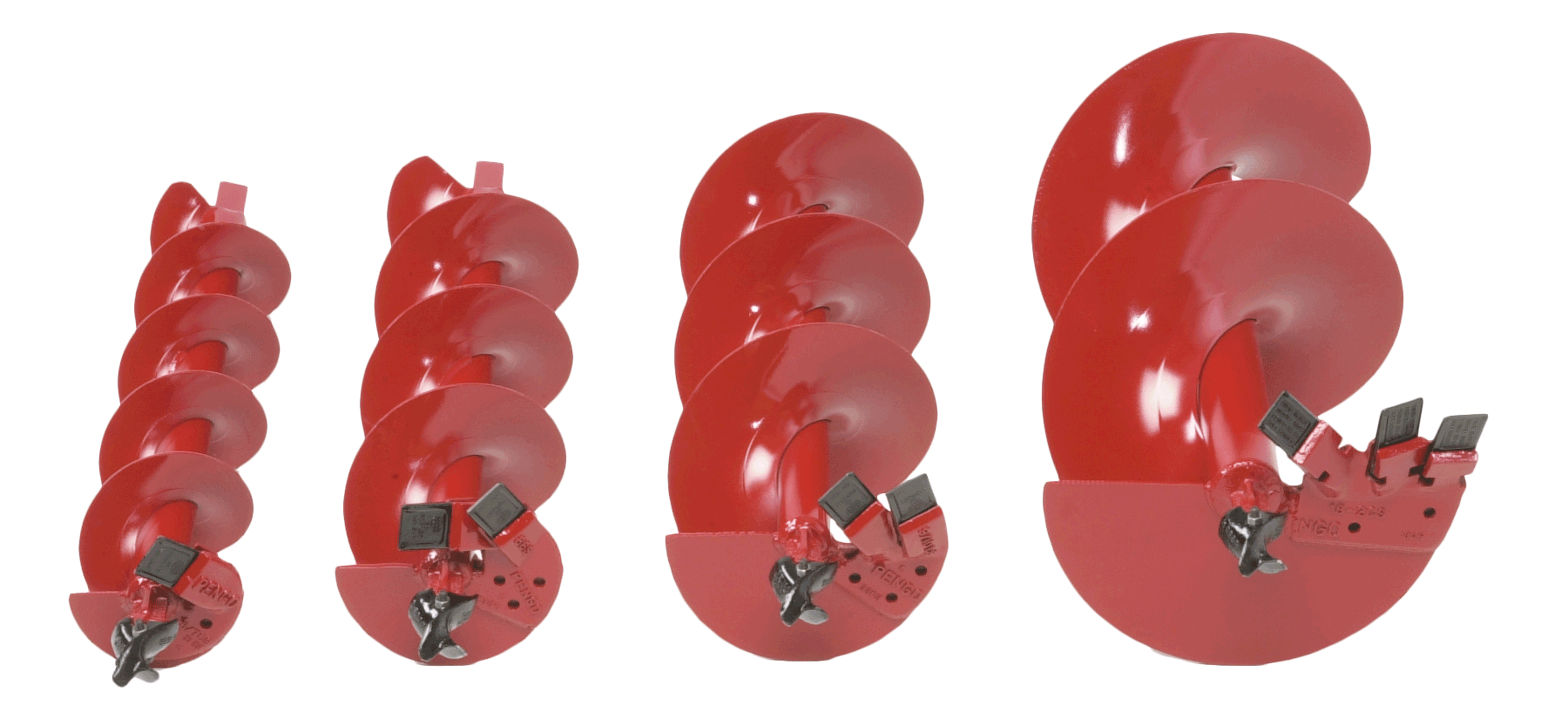

Augers, Points & Blades Wear Issues

Maximize Drill Performance

Operators sometimes forget that points and blades need regular maintenance just like an earth drill does. Too often, these small pieces are forgotten in the day-to-day shuffle of drilling projects. However, forgoing routine maintenance on these critical parts can lead to a decline in drilling performance or even a complete breakdown on the jobsite.

Proper maintenance and replacement of common wear parts keeps your earth auger operating at peak performance. Like the drills they are mounted on, augers, points and blades require routine maintenance.

- Check the placement of the points and blades every day. Misalignment might cause the auger to vibrate excessively or “walk” during use.

- Ensure you’re using the right points and blades for the soil. Standard options work for loamy soils or areas with few rocks while hard clay or frozen ground requires carbide blades. Having the right points and blades will protect the auger from damage and make your drilling project easier.

- Replace worn attachable points and blades before they reach the auger flighting. Operators can replace these parts quickly with basic hand tools, such as a wrench or ratchet set. To learn more, check out our video below.

- If the blades wear down far enough to damage the flighting, operators will need to repair the auger flighting by welding the material or replace the entire auger.

- A good rule of thumb is to never operate a drill with damaged or missing parts, which includes the auger.

Heavy-Duty Auger Point

Our earth augers feature abrasive-resistant steel and hard surfacing on the edges of the points and blades. Another benefit of working with Little Beaver is that our points and blades are reversible, which means you get twice as much work out of one point or blade.

The time put into maintaining smaller wear parts protects against larger repair costs if the drill is damaged or breaks. Keep an eye on maintenance schedules to prolong the life of your Little Beaver earth drills.